Beyond the Data: How Analytics and Teamwork Drive Real Manufacturing Success

Published:

📊 Strong Analytical Skills in Action: Turning Data into Dollars

My approach has always been to start with the numbers to understand the reality of the shop floor. By translating operational data into actionable insights, I can pinpoint the root cause of an issue and develop a targeted solution.

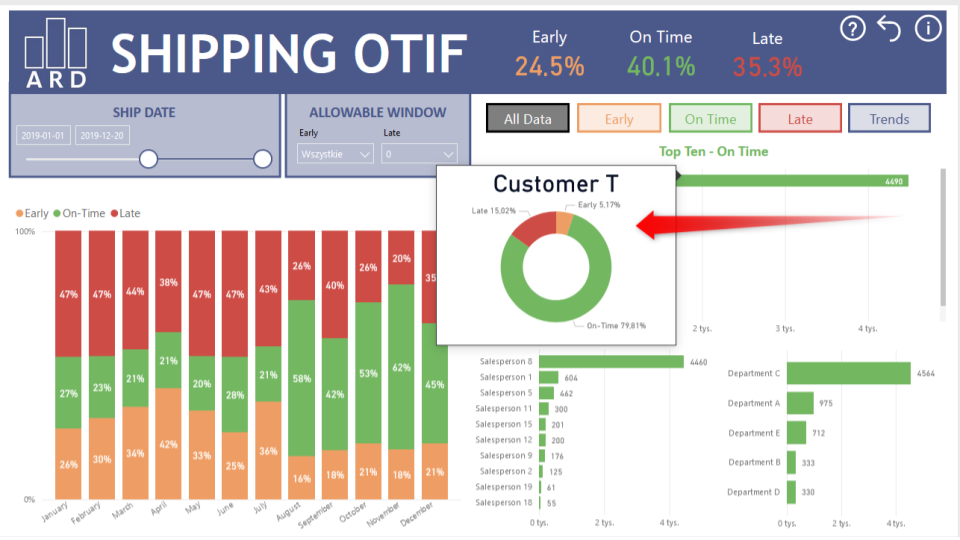

A real-time dashboard provides instant visibility into key metrics like supplier wait times and goods receipt status.

For example, a real-time dashboard can instantly highlight inefficiencies that were previously hidden in manual reports.

🔍 Summary of Applied Analytical Methods

| Analytical Method | Application | Quantifiable Result |

|---|---|---|

| Statistical Process Control (SPC) | Analyzed the performance of 50 injection molding machines. | 9% reduction in cycle time. |

| Methods-Time Measurement (MTM) | Analyzed a sub-assembly line to identify waste. | 57% increase in production rate. |

| Data Modeling & Simulation | Redesigned packaging and optimized container loading. | 98% container utilization on key routes. |

🤝 Success Through Interdisciplinary Teamwork: Breaking Down Silos

Analytical insights are only powerful if they can be implemented, and that requires getting buy-in and collaboration from every corner of the organization. I thrive on leading projects that bring diverse teams together to achieve a common goal.

- When we needed to improve our Global Quality Audit score, I didn’t just write a report. I formed a team and led Kaizen Breakthrough events that brought together experts from Quality, Engineering, and the leadership team.

By walking the floor together and analyzing the process from every angle, we were able to move from a major finding to a minor one.

To digitalize our goods receipt process, I partnered closely with the SAP technical team. My role was to translate the needs of the warehouse operators into technical requirements—ensuring the final solution was both efficient and user-friendly, and fully integrated with the SAP MM module.

- When developing a new plant-wide training program, I collaborated with HR and all department heads to conduct a comprehensive needs analysis. This ensured that the final plan was strategic, targeted, and had full organizational support.

💡 Final Thought

Ultimately, operational excellence isn’t just about finding a problem and fixing it. It’s about building a system and a culture where data is used to empower people—and where people from all disciplines can work together to achieve remarkable results.