Driving Excellence in the Warehouse: Mastering Step 4 of Autonomous Maintenance at Colgate Palmolive

Published:

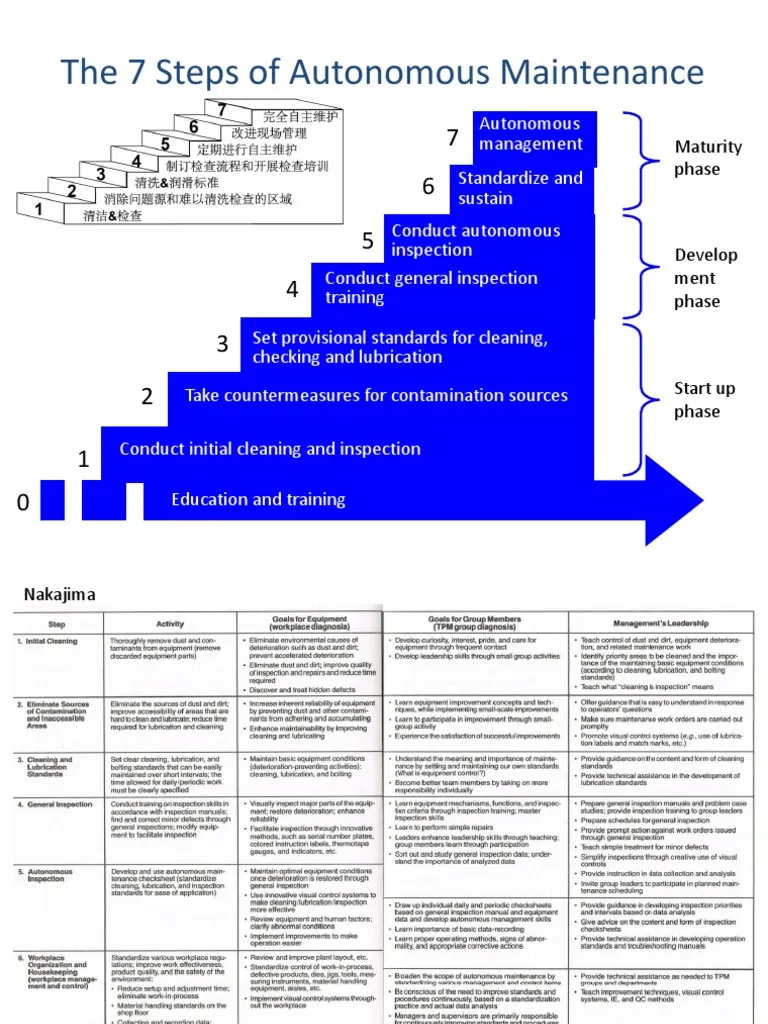

In the dynamic environment of a Colgate Palmolive warehouse, operational excellence is key. Autonomous Maintenance (AM) is a foundational strategy that empowers our teams to ensure equipment reliability and drive efficiency. By progressing through the 7 steps of AM, we cultivate a culture of ownership and proactive care, with Step 4 marking a pivotal stage in this journey.

The 7 Steps of Autonomous Maintenance: A Brief Overview

Autonomous Maintenance is a structured, seven-step process designed to gradually increase operator skill and equipment ownership:

- Initial Cleaning & Inspection: Operators thoroughly clean their equipment to identify and tag any abnormalities like leaks, cracks, or loose bolts.

- Eliminate Contamination & Improve Access: Address the root causes of dirt and grime identified in Step 1 and make equipment easier to clean and inspect.

- Create Tentative Standards: Establish initial standards for cleaning, lubrication, and inspection to maintain the equipment’s basic condition.

- General Inspection: Train operators on detailed inspection of key equipment subsystems (mechanical, electrical, etc.) to deepen their technical understanding.

- Autonomous Inspection: Operators independently execute their inspection checklists, refining and improving the standards based on their experience.

- Standardize the Workplace: Organize the entire workplace, not just the equipment, by standardizing all processes, tools, and procedures.

- Full Self-Management: The team operates with full autonomy, continuously analyzing data and improving equipment performance and processes.

Defining Step 4: General Inspection

Step 4 is where operators evolve from caretakers to skilled inspectors. The goal is to train them to understand the “why” behind equipment functions and to detect subtle issues before they cause breakdowns.

Our Application at the Colgate Palmolive Warehouse:

Our approach to Step 4 focuses on empowering operators who manage key warehouse assets like conveyors, sorters, packing machines, and forklifts.

Targeted Training: We are deploying concise, equipment-specific training modules, co-developed by maintenance experts and operators, to build deep inspection skills.

Visual Standards: Simple, visual checklists and one-point lessons (OPLs) are placed on equipment to guide operators through systematic inspections.

Enhanced Abnormality Handling: A tiered tagging system helps operators classify and communicate issues effectively, streamlining the maintenance workflow.

Collaborative Coaching: Maintenance technicians act as coaches, working alongside operators to transfer knowledge and reinforce best practices directly on the warehouse floor.

Overcoming the Challenges of Implementation

Resistance to Change: Shifting the mindset from “I operate, you fix” to one of shared ownership requires consistent communication and demonstrating the value for everyone involved.

Time Commitment: Dedicating time for cleaning, training, and inspections can be difficult in a high-demand environment. This requires careful planning and unwavering management support to protect that time.

Retaining Previous Steps: As the team advances to more complex inspections in Step 4, there’s a risk of neglecting the foundational disciplines of cleaning and basic standards established in Steps 1-3. Maintaining these habits is critical for long-term success.

Sustaining Momentum: The initial enthusiasm can wane. It’s crucial to celebrate small wins, track progress visibly, and continuously reinforce the importance of the AM program.