MTM Work & Time Studies

📄 Project Description:

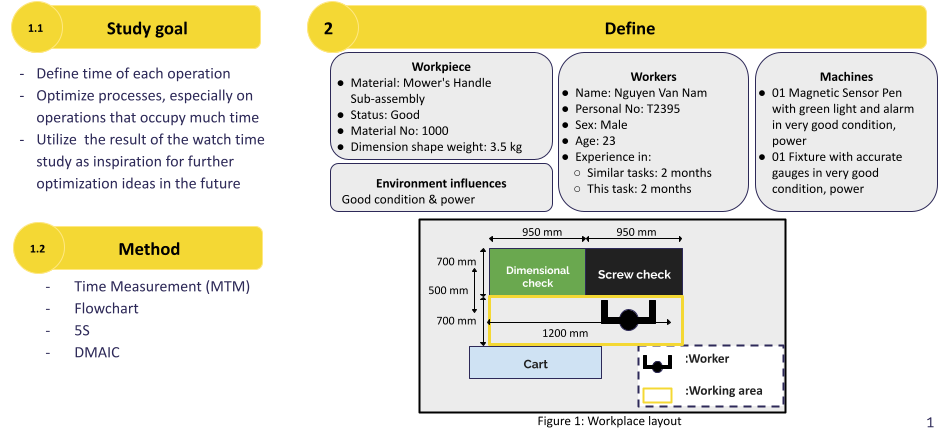

We conducted a detailed Methods-Time Measurement (MTM) study to analyze and optimize a sub-assembly process, identifying and quantifying all value-added and non-value-added activities.

🏆 Key Achievements:

- The analysis identified that non-value-adding activities accounted for 28.66% of the throughput time.

- The subsequent optimized process successfully increased the production rate from 80.68 to 126.98 pieces/hour, a 57% improvement.

👉 Click to visit my project

🛠️ Relevant Skills Demonstrated:

Time & Motion Study, MTM, Value Stream Mapping, Process Optimization, Bottleneck Analysis.